Linde’s latest high-performance freezing technology with CRYOLINE CX600 Spiral Freezer is presently available in Australia for a wide range of food applications from seafood and poultry, to dumplings and ready-made meals.

This highly compact unit from Linde features a unique 600mm wide belt design allowing for an easy integration into existing production lines with high output and less floor space requirements.

It contains a solid surface flat belt, instead of an open weave belt which is commonly seen in most spiral freezers. This provides an additional benefit of being able to work with different products especially those with sensitive to weave belt marking, such as coated products like chicken schnitzels.

This spiral freezer delivers higher yields, quicker freezing times and better product quality. In fact, depending on the food application, it has the capacity to produce up to 3,000 kilograms per hour while using only 16m2 of floor space.

If you want to upgrade your existing spiral freezer technology, increase production capacity and reduce floor space, then you need to find out information about the CRYOLINE CX600 Spiral Freezer.

Using advanced cross-flow technology, the CRYOLINE CX600 Spiral Freezer significantly reduces freezing time, therefore improves cryogen efficiency and reduces the overall freezer size. This provides up to 50% higher heat transfer rate compared with conventional spiral freezers by covering nearly 100% of the belt freezing surface area with a high-velocity gas flow.

This high heat correlates with a high operating efficiency, as the freezer can be functioned at warmer temperatures. Steady-state losses are lessened due to the reduced overall box size and weight.

The spiral freezer acts as a heat exchanger, in which the cryogen is sprayed directly onto the product, which efficiently extracts heat from it. The cryogenic gas spreads around the product at high velocity and then extracted by the exhaust system.

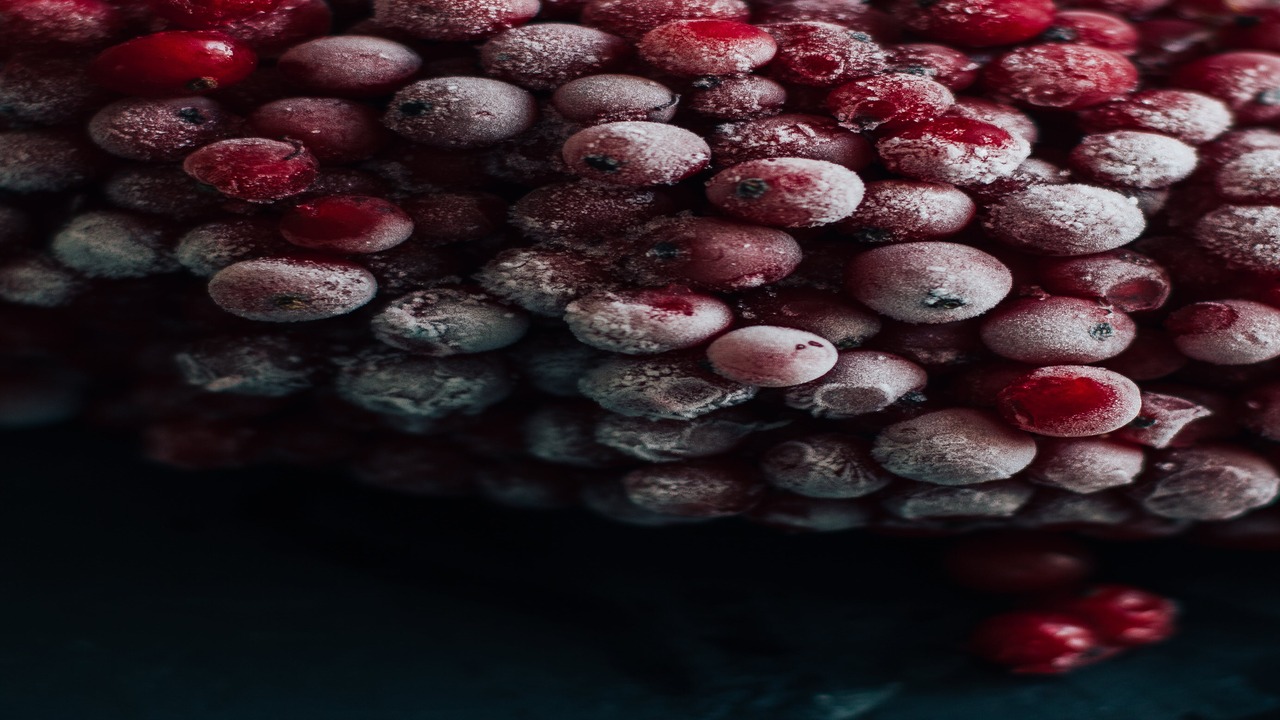

Freezing with cryogens allows for a very low operating temperature and also a very fast freezing action. This preserves the shape and quality of the product and provides increased product yield.

The CRYOLINE CX600 Spiral Freezer has an HMI (Human Machine Interface) touch screen control. The main menu displays the current product, motor speeds, safety status, machine messages, selected operational mode, freezer temperature, historical data, and access to other screens.

In case if there is a fault, then the operator is given a specific information about the cause of the fault in the message display area. Recipes can be simply loaded by accessing the recipe screen, allowing the storage/recall of the operational parameters of all product types and thus ensuring consistent operation.

The CRYOLINE CX600 Spiral Freezer can use either carbon dioxide or nitrogen as the cryogenic medium, ensuring maximum efficiency and flexibility.

Linde’s CRYOLINE freezing solutions are especially designed for hygiene and ease of sanitation, including the new CX600 Spiral Freezer. Made from laser-cut stainless steel with sloped surfaces, rounded corners and polished welds that simplify washdown, it helps to have total accessibility to all internal parts and areas and saves your time and money.

It has a built-in self-cleaning belt washer system, making it easy to maintain hygienic sanitation practices while increasing productivity with less cleaning and downtime.

Be one of the first in Australia to implement the latest spiral freezer technology in your manufacturing process.

With years of experience in cryogenic freezing solutions, BOC is committed to using their expertise to help improve outcomes and productivity for Australian businesses.