(Commonwealth) _ Lödige Industries, a global leader in logistics systems, has recently finalized the installation of an advanced automated storage and retrieval system at The Hongkong Electric Co., Ltd. (HK Electric)’s Electric Tower in Ap Lei Chau, Hong Kong Island. The state-of-the-art system incorporates an elevating transfer vehicle (ETV) designed for efficiently handling heavy cable drums and transformers. This innovative solution not only optimizes warehouse space utilization and enhances safety protocols but also boosts material handling efficiency and streamlines inventory management processes. Beyond its immediate benefits, the system establishes a robust foundation for the company’s future expansion and evolution. Having illuminated homes and businesses in Hong Kong since 1890, HK Electric boasts a longstanding reputation for providing a secure and highly reliable electricity supply at a reasonable cost to customers on Hong Kong and Lamma islands. Notably, HK Electric has maintained an electricity supply rating of over 99.999% since 1997, surpassing the performance of many top cities globally. This remarkable achievement positions the company among the world’s leading performers in electricity supply reliability. To consistently deliver such stability and dependability, the implementation of modern storage systems that align with the evolving demands of the industry is crucial.

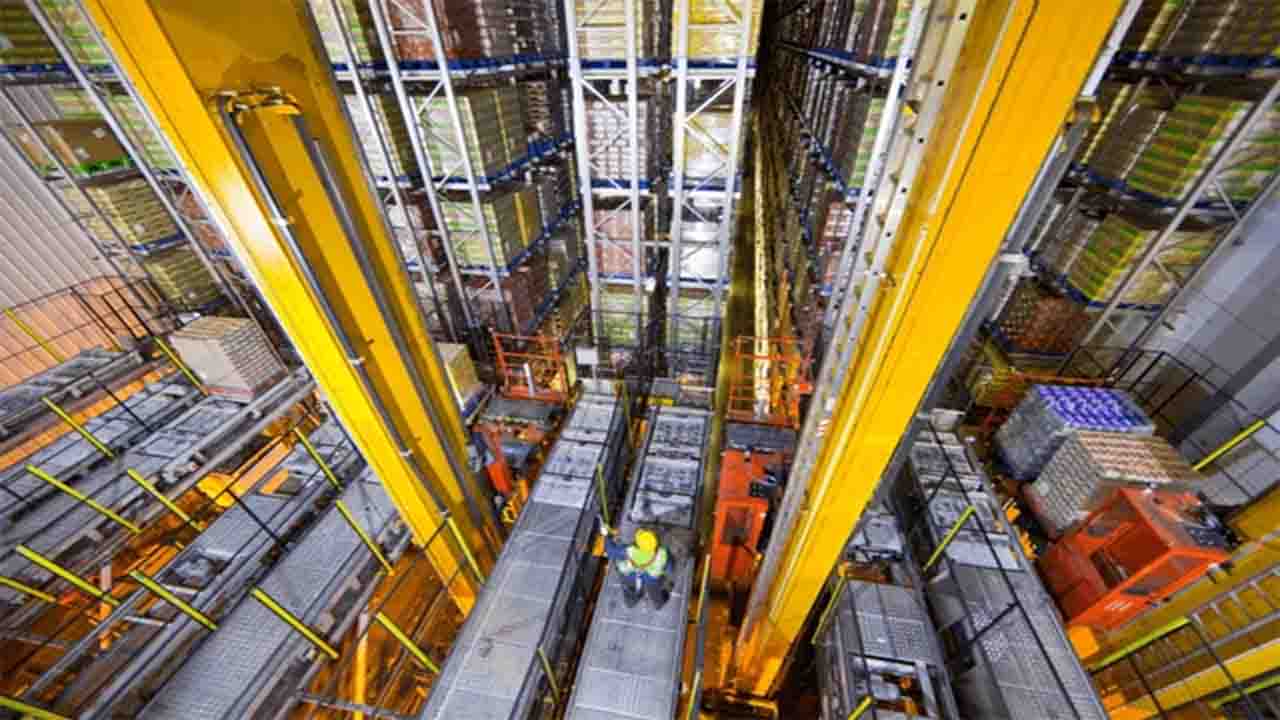

Faced with the constraint of a non-extendable storage area of 800 m², the need for a multi-storey solution became imperative to accommodate growing demands. Additionally, the challenge of storing cable drums, each weighing 5.3 tons, without risking damage, along with the complexities of retrieval and stock tracking, required an innovative approach. The newly implemented fully automated 4-level system, serviced by an ETV, now enables the customer to store a significantly larger amount of stock within the same footprint, ensuring safety and damage-free storage. The warehouse can now manage up to 293 storage positions efficiently. The tailored system comprises high-quality hardware components, including powered decks and conveyors, complemented by intelligent control software. The integration of automated processes significantly reduces the physically demanding manual labor involved in transporting and storing cable drums. This not only provides HK Electric with real-time visibility and control over inventory but also enhances work routines for its staff.

Alan So, Head of Commercial Services at HK Electric, emphasizes the company’s commitment to health and safety, placing it among their top priorities. He highlights the promotion of automation and innovation as essential tools to enhance productivity and safety in business activities. The collaboration with Lödige Industries has resulted in a more efficient cable drum inventory management system, with the automated ETV system optimizing storage density and safety. So acknowledges Lödige Industries’ support throughout the entire process, from planning and permits to construction, testing, and training. The system now offers control over drum storage, retrieval, and visibility, laying a foundation for future growth and evolving needs.

Joman Chong, General Manager of the BPS Global Group involved in the project, expresses enthusiasm about the comprehensive solution presented to HK Electric. The collaboration with Lödige Industries is seen as a revolutionary approach to inventory management and storage optimization. Chong anticipates further strengthening their partnership with Lödige Industries as they collectively develop their businesses. Lödige Industries, a prominent global logistics systems supplier specializing in moving heavy goods, expands its expertise to the energy sector. Nicholas Tripptree, Managing Director for Asia-Pacific at Lödige Industries, notes that the project for HK Electric demonstrates their ability to address complex material handling requirements in the energy sector. He emphasizes that their extensive knowledge in transporting heavy goods is transferable to challenges in other industries, allowing successful design and implementation of projects with similar requirements for customers across various sectors.