(Commonwealth) _University of Birmingham Enterprise has introduced EvoPhase, a groundbreaking initiative designed to enhance existing and new process equipment used in the mixing, blending, storage, and stirring of granular materials. EvoPhase harnesses the power of evolutionary AI algorithms and simulations of particulate behavior within systems like industrial mixers to evolve optimized designs for mixing blades and vessel shapes or sizes. The revolutionary approach of “evolutionary design” introduced by EvoPhase is incredibly versatile, extending its application to a wide range of process equipment categories. These encompass not only industrial mixers but also mills, dryers, roasters, coaters, fluidized beds, and stirred tanks, among others. By doing so, EvoPhase offers a comprehensive solution for optimizing equipment used in the processing of granular materials across various industries. The potential impact of this approach on industries worldwide is profound. It is anticipated to yield substantial cost savings and significantly enhance energy efficiency. With the ability to fine-tune and optimize diverse types of machinery, EvoPhase provides a universal solution to improve the performance and sustainability of industrial processes on a global scale, offering long-term benefits for businesses and the environment.

EvoPhase is established as an Operating Division, offering rapid access to cutting-edge services provided by Birmingham’s academic innovators. The founding team consists of four key figures: CEO Dominik Werner, CTO Leonard Nicusan, COO Jack Sykes, and CSO Dr. Kit Windows-Yule, all hailing from Birmingham’s School of Chemical Engineering. Their extensive experience in digital modeling and simulation of industrial processes positions EvoPhase to tackle challenges that conventional R&D methods often struggle to resolve. CEO Dominik Werner emphasizes the complexity of granular materials in industrial processes, noting that up to 50% of the world’s products involve these materials. Granules, he explains, exhibit various states, transitioning from solid when contained to liquid-like when poured, and even gas-like when dispersed. Understanding and characterizing granules present a unique set of challenges in industrial processes.

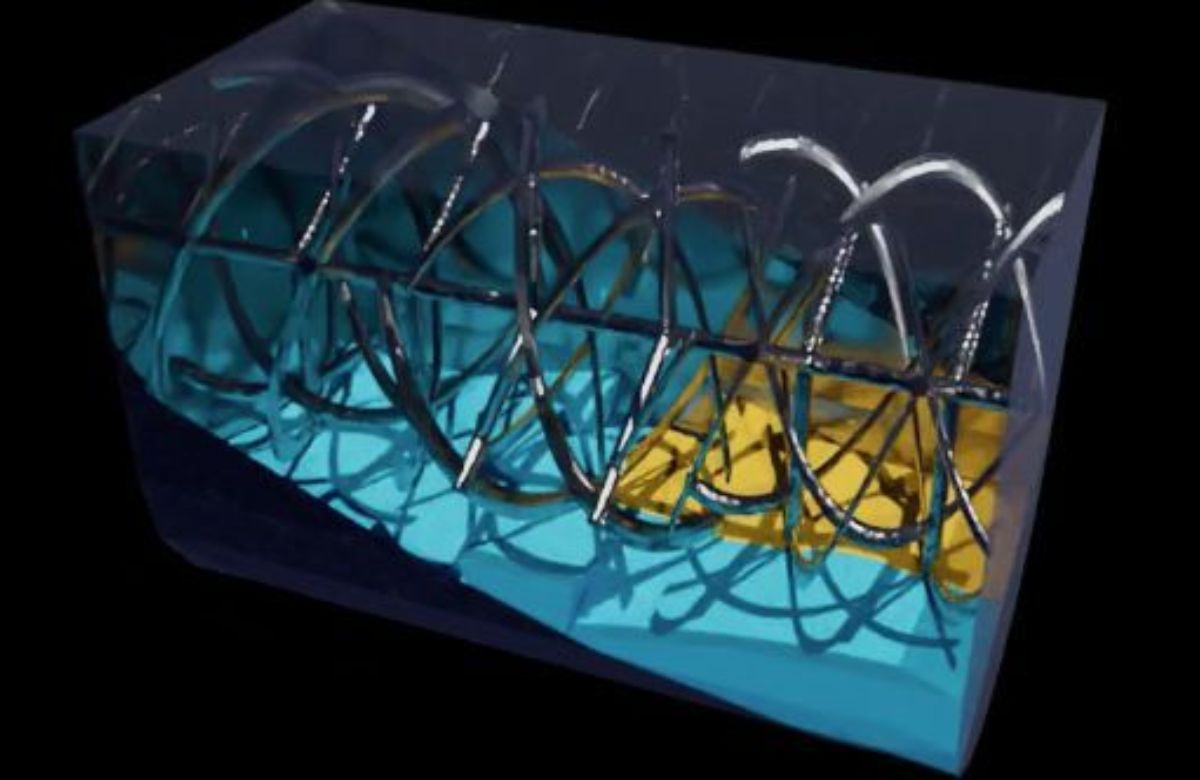

EvoPhase’s approach leverages a novel AI technology known as Highly-Autonomous Rapid Prototyping for Particulate Processes (HARPPP). This technology mimics natural selection, allowing the testing of evolved designs to identify the most optimal ones. Users can define multiple parameters for optimization, facilitating the evolution of designs that meet specific targets, such as power consumption, throughput, and mixing efficiency, without sacrificing one for the other. Additionally, EvoPhase employs the Discrete Element Method (DEM), a numerical technique for predicting the behavior of granular materials by computing the movements of individual particles. These computations can be validated using Positron Emission Particle Tracking (PEPT), a technique developed at Birmingham, which is a variant of positron emission tomography (PET), a medical imaging technique.

Leonard Nicusan highlights the range of technologies at EvoPhase’s disposal, including material characterization, digital model development, experimental imaging and validation, process condition optimization, geometric design enhancement, scale-up, and predictive model development. This comprehensive approach is applicable to the design of powder, granule, and fluid processing equipment across diverse industries, promising cost savings by increasing energy efficiency, improving mixing performance, and enhancing throughput. EvoPhase is poised to revolutionize the optimization of process equipment for granular materials, driven by cutting-edge Driven by cutting-edge AI and simulation technologies, EvoPhase, spearheaded by a team of distinguished experts from the University of Birmingham, is on a mission to confront the intricate challenges presented by granular materials in diverse industrial processes. The innovative initiative has set its sights on delivering comprehensive and cost-effective solutions that not only optimize energy efficiency but also enhance productivity in industrial settings. By leveraging its unique blend of advanced AI algorithms and simulations, EvoPhase stands as a beacon of innovation, poised to revolutionize the way industries worldwide approach the processing of granular materials, ultimately ushering in a new era of sustainability and efficiency.