By Wasana Nadeeshani Sellahewa

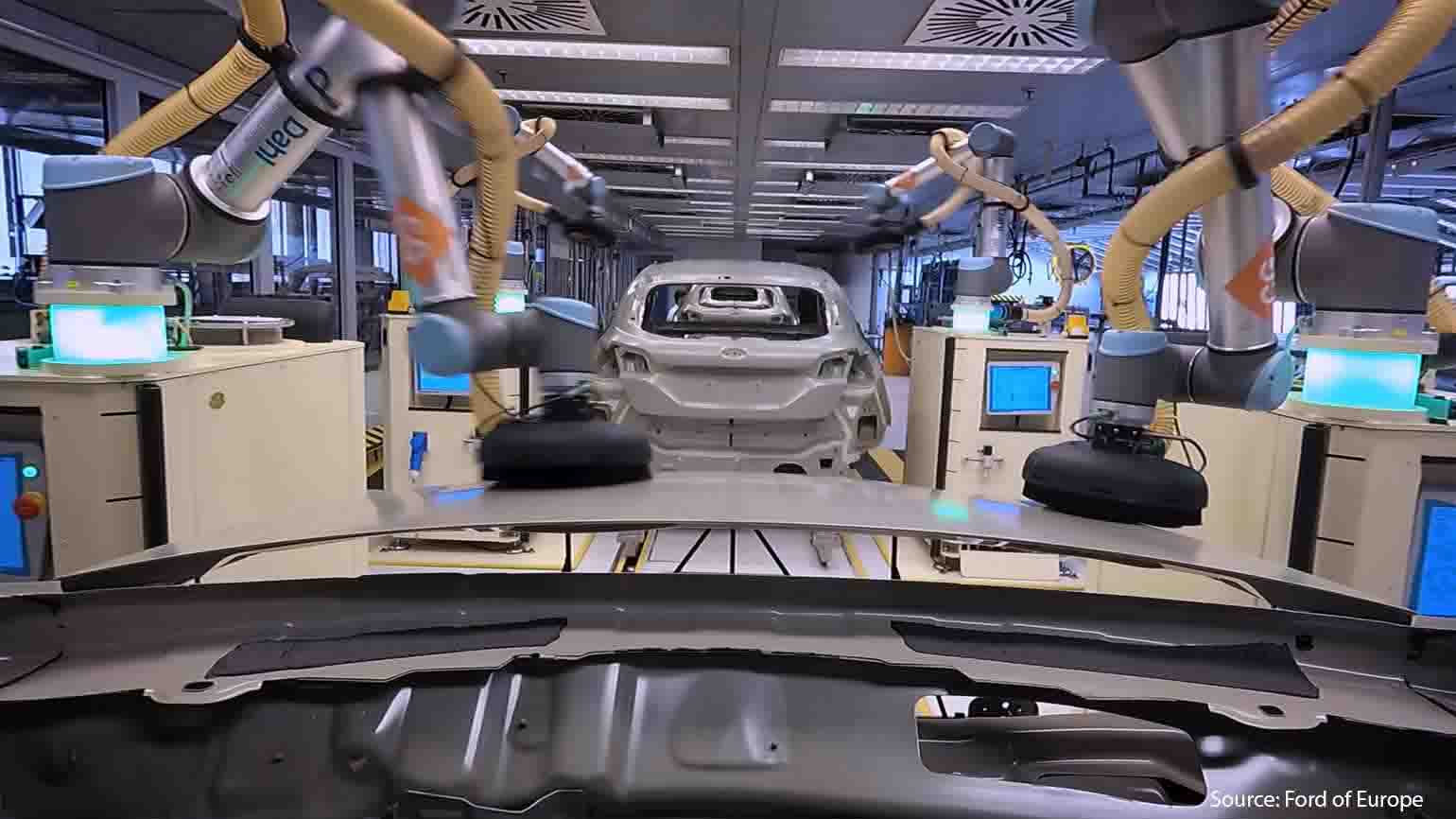

(Commonwealth) _ People and robots working together outperform robots or humans working alone. This is further backed by a 2014 MIT research that evaluated the impact of human-robot cooperation and discovered an 85% reduction in worker idle time while working beside collaborative robots. The automobile sector was an early adopter of classical industrial robots. It was, in fact, one of the first to widely deploy cobots. According to the International Federation of Robotics, cobots grew faster than typical industrial robots in 2019. Automation is now present in practically every element of auto production, from the fabrication of parts and subassemblies at Tier 1 and 2 suppliers through the final product rolling off the line at OEM production facilities. Let us have a look.

Although the automobile industry has been embracing robots for decades, there are still some operations, mostly on the assembly side, that rely heavily on manual labor. Because most vehicle manufacturing takes place in cities, there is no extra space to expand or accommodate massive robots. As a result, one of the advantages of cobots is their adaptability. After a risk assessment, they may be mounted anywhere and deployed with people. Cobots have a compact footprint, which means they can be simply placed into current production lines, installed on a pedestal, or put into a mobile platform for urban vehicle builders. They are effective in a wide range of applications.

Bajaj Auto, one of the world’s largest motorcycle manufacturers, for example, installed the first collaborative robots in India in 2010, and now has over 100 cobots on its Chakan production line. The factory grounds were labor-intensive, space-constrained, and physically demanding for the company’s workers, half of whom were women. Bajaj decreased ergonomic risks by adopting cobots, which streamlined tasks and increased consistency. Material handling, machine tending, patented decal application, vision application, bolt tightening, and welding were all supported by over 100 cobots. Manufacturing has been standardised and improved as a result of the compactness, versatility, and ease of use of UR’s collaborative robots. The cobots aided in the creation of high-quality bikes while also upskilling and enabling the company’s employees to work with them.

Continental, one of the world’s major tire producers, has incorporated cobots into their equipment operated by humans at their manufacturing sites in India. Continental did not have to incur any additional costs due to the collaborative nature of cobots, such as protection fences or safety curtains, which are required for regular robots. The cobot enabled the removal of human mistakes, reduced ergonomic hazards, and accelerated the process, guaranteeing the brand’s high quality standards.

UR is concerned about its customers and is always improving its product offerings. For example, our new cable suite for our e-Series platform was created in response to automakers’ requests for greater flexibility in integrating our e-Series robots into their manufacturing lines.

The Universal Robots UR16e has a tiny footprint and a substantial payload of 16kg (35.3 lbs.). It is suited for use in heavy machine tending, material handling, packing, and screw and nut driving applications. This powerful robot is ideal for heavy end-of-arm tooling and multi-part handling, as well as attaining reduced cycle times. “

After a comprehensive examination of the choices that were available in the market, Bajaj Auto picked Universal Robots largely owing to the collaborative nature of the robots,” said Vikas Sawhney, General Manager Engineering (Robotics and Automation) Bajaj Auto. The compactness, quick payback period, flexibility, light weight, cost-effectiveness, precision, and safety of Universal Robots’ products eventually convinced Bajaj Auto of Universal Robots’ appropriateness for its standardized offers.”

In a word, UR’s cobots are suitable for small and large businesses aiming to increase their production quality and consistency. Cobots are a godsend to the organizations that use them since they increase pace while also maintaining employee safety. Cobots are the future of innovation in India, with cheap maintenance and high ROI in a short period of time.