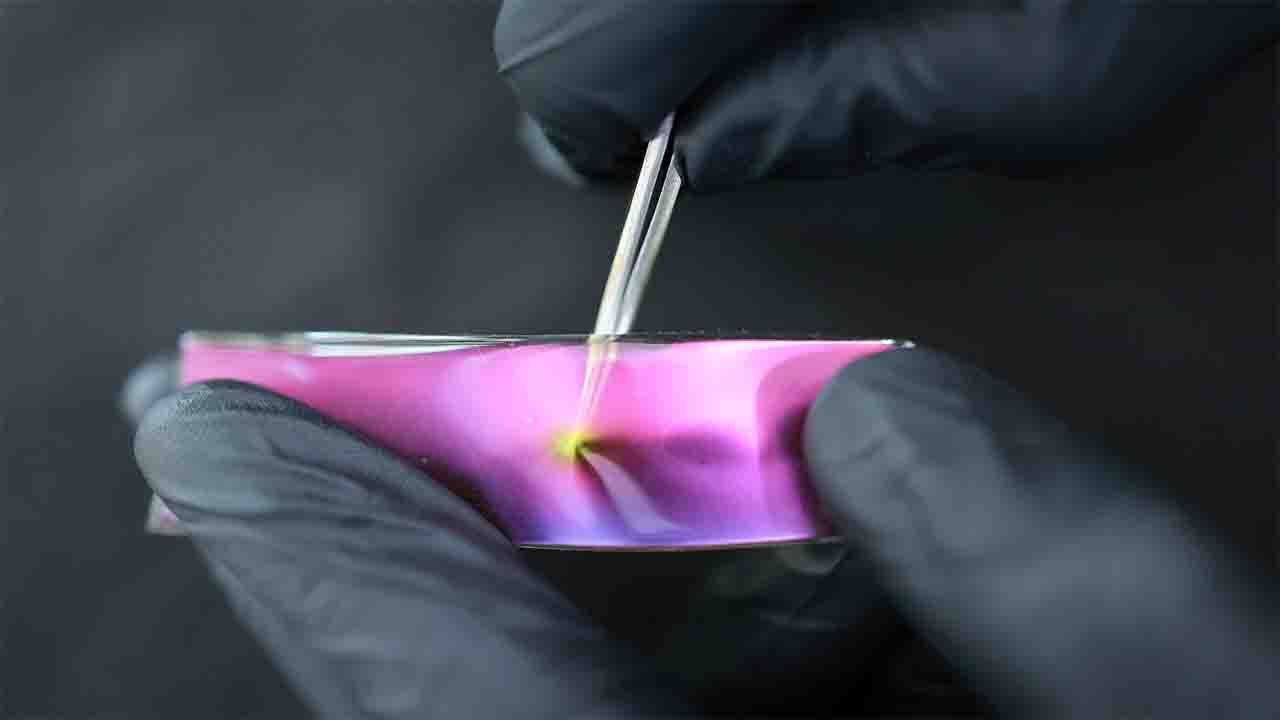

Science & Technology, India (Commonwealth Union) – The Indian Institute of Science (IISc) researchers have pioneered the creation of flexible films that display vibrant hues solely through their physical makeup, eliminating the necessity for conventional pigmentation. As these films are stretched, their colors shift in response to mechanical stress.

The team developed an innovative, cost-efficient, and easily scalable method for crafting these films. It entails the evaporation of gallium metal to generate nano-sized particles on a flexible substrate, enabling the simultaneous production of numerous structural colors sensitive to mechanical alterations.

Gallium metal, with its unique properties and versatile applications, plays a crucial role in various technological advancements and industrial processes. From revolutionizing electronics and semiconductors to aiding in cancer treatment and beyond, gallium continues to prove its worth in diverse fields. As research and innovation progress, the full potential of gallium metal is yet to be realized, promising exciting prospects for the future of science and technology.

Furthermore, the researchers have demonstrated the versatility of these films across various applications, ranging from intelligent bandages and motion detectors to reflective displays.

“This is the first time that a liquid metal like gallium has been used for photonics,” added Tapajyoti Das Gupta, Assistant Professor in the Department of Instrumentation and Applied Physics (IAP), who is also corresponding author of the study that appeared in Nature Nanotechnology.

Certain natural elements, such as gemstones, mollusc shells, and peacock feathers, boast inherent vibrancy, owed to the intricate interplay of light with micro- or nano-scale structures. For instance, opal exhibits hues stemming from minute silica spheres, mollusc shells showcase iridescence courtesy of calcium carbonate-based platelets, and peacock feathers dazzle with segmented ribbons on the top of cylindrical structures.

Inspired by nature’s colorful creations, structurally tinted materials have found diverse applications in displays, wearable electronics, visual sensors, and anti-counterfeiting measures. Recently, scientists have embarked on designing materials capable of dynamically altering their color under external mechanical stimuli.

The team from IISc embarked on an innovative exploration of gallium, an underexplored element for such purposes due to its high surface tension, hindering nanoparticle formation. Gallium, being a liquid metal at ambient temperature, demonstrates potent interactions with electromagnetic radiation through its nanoparticles. Surmounting the challenge of surface tension, the team devised a method utilizing the unique properties of polydimethylsiloxane (PDMS), a biocompatible polymer, to fabricate gallium nanoparticles.

Upon stretching the substrate, researchers observed an intriguing phenomenon: the material exhibited varying colors corresponding to different levels of strain. Their hypothesis suggested that the arrangement of gallium nanoparticles deposited on the substrate interacted with light in distinctive manners, thus yielding diverse hues.

To delve into the substrate’s contribution to color manifestation, the team devised a mathematical framework.

PDMS, a polymer synthesized by blending two liquid components—an oligomer as well as a cross-linker—undergoes a chemical reaction to solidify. What intrigued the researchers was the role of unreacted oligomer, remaining in a liquid state, in stabilizing gallium nanoparticle formation on the substrate. Upon stretching, these liquid-like oligomers infiltrated the gaps between nanoparticles, altering their spacing and light interaction, consequently leading to color changes. Experimental validation in the laboratory corroborated the model’s predictions. Through fine-tuning the ratio of oligomer to cross-linker, the researchers achieved a spectrum of colors.

“We show that the PDMS substrate not only holds the structure, but also plays an active role in determining the structure of gallium nanoparticles and resulting colouration,” explained Renu Raman Sahu, PhD student in IAP who was also the lead author. Following 80,000 cycles of stretching, the material demonstrated the capability to display a repeatable colour alteration, demonstrating how reliable it was.

Researchers of the study pointed out that traditional methods like lithography for fabricating such materials require numerous steps and are expensive to scale up. To address this challenge, the team developed a single-step physical vapor deposition technique. This method involves evaporating liquid gallium metal and depositing it onto a PDMS substrate, enabling the production of flexible, structurally colored films approximately half the size of a palm.

These films hold promise for a variety of applications. For instance, the team showcased a body movement sensor as one potential application. By attaching a strip of the film to a finger, the color of the film changed as the finger was bent, providing real-time movement detection as indicated by the researchers.