Science & Technology, Canada (Commonwealth Union) – Advanced structural materials often face a protracted journey from laboratory development to practical industrial applications. Nevertheless, researchers at the University of Toronto (U of T) are employing machine learning to expedite this process.

Yu Zou, an assistant professor in the Faculty of Applied Science & Engineering’s Department of Materials Science and Engineering, emphasizes the significance of microstructure design in material development. He notes that traditional methods, reliant on experiments or simulations, can consume years, and even decades, in the quest to pinpoint the ideal microstructure.

Zou and his research team are dedicated to hastening the discovery of innovative structural materials. Their recent publication in Materials Today unveils a groundbreaking end-to-end framework tailored for shaping the microstructure of Ti-6Al-4V, a ubiquitous titanium alloy extensively used in the aerospace and biomedical sectors.

“This work could enable materials scientists and engineers to discover microstructures at speeds unseen before, by simply inputting their desired mechanical properties into the framework,” explained PhD candidate Xiao Shang, who is the lead author of the paper.

To initiate their work, the researchers commenced by instructing two deep-learning models to make precise predictions of material properties based on their microstructures. Subsequently, they melded a genetic algorithm with these deep-learning models to complete the materials-by-design cycle. This integration empowers the framework to create optimal material microstructures, aligning them with desired mechanical properties.

Shang indicated that, in a span of under eight hours, they were able to pinpoint titanium alloy microstructures that exhibited the exceptional combination of high strength and stiffness essential for fortifying the structural elements of aircraft.

“We also designed titanium alloys with the same chemical compositions as the former but with different microstructures that are about 15 per cent more compliant for biomedical implants compatible with human bones.”

The development of their deep learning models presented the researchers with numerous challenges. This included the creation of their extensive dataset comprising nearly 6,000 diverse microstructures through simulation, a task made feasible by harnessing the immense computing capabilities of supercomputers at the Digital Research Alliance of Canada.

Shang pointed out that throughout their journey, they encountered situations where their chosen deep-learning models and optimization algorithms didn’t perform as well as they expected. However, they persevered, adhering to their research plan and actively exploring new approaches to enhance model workability.

Notably, their research received recognition when it earned a Poster Prize at the 2023 Accelerate Conference, hosted by the Acceleration Consortium at the University of Toronto. Earlier in the year, the Consortium was awarded a historic $200-million grant to support advanced materials discovery using self-driving labs. Furthermore, this work benefits from support provided by the University of Toronto’s Data Sciences Institute and the Centre for Analytics and Artificial Intelligence Engineering. Both the Acceleration Consortium and the Data Sciences Institute represent strategic initiatives at the U of T.

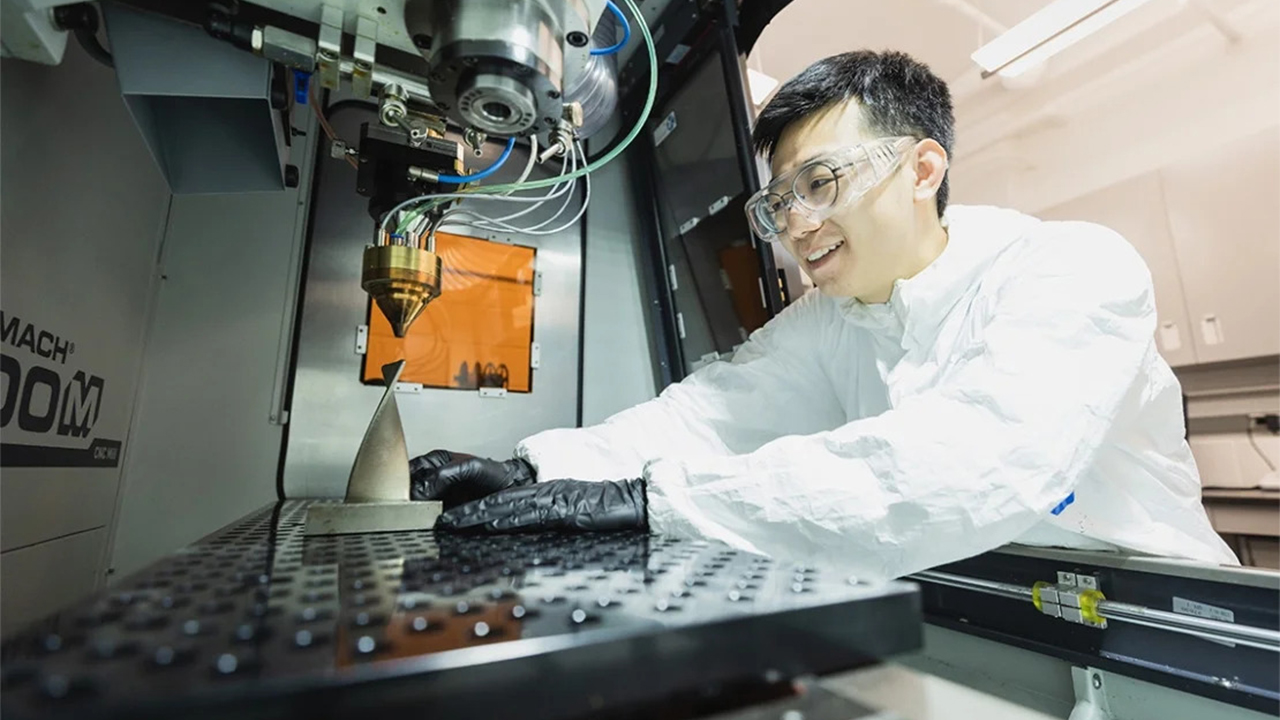

As they look ahead, the researchers are committed to optimizing and enhancing additive manufacturing technology to further advance this innovative framework. PhD candidate Tianyi Lyu, who co-authored the paper alongside fellow PhD candidate Jiahui Zhang, both specializing in metal additive manufacturing, indicated that they are enhancing the quality and reliability of metal additive manufacturing, unlocking its potential to customize material microstructures during the printing process. Yu Zou, is a member of the Acceleration Consortium.

“For example, with traditional technology, it is close to impossible to tailor biomedical materials for different patients. But we want to enable the future of personalized biomedical implants by making it possible to print the shape and mechanical properties that match a patient’s needs in only a few days.”

The role of machine learning continues to advance research like never before with the ability to explore and connect the dots to large quantities of data.