By Wasana Nadeeshani Sellahewa

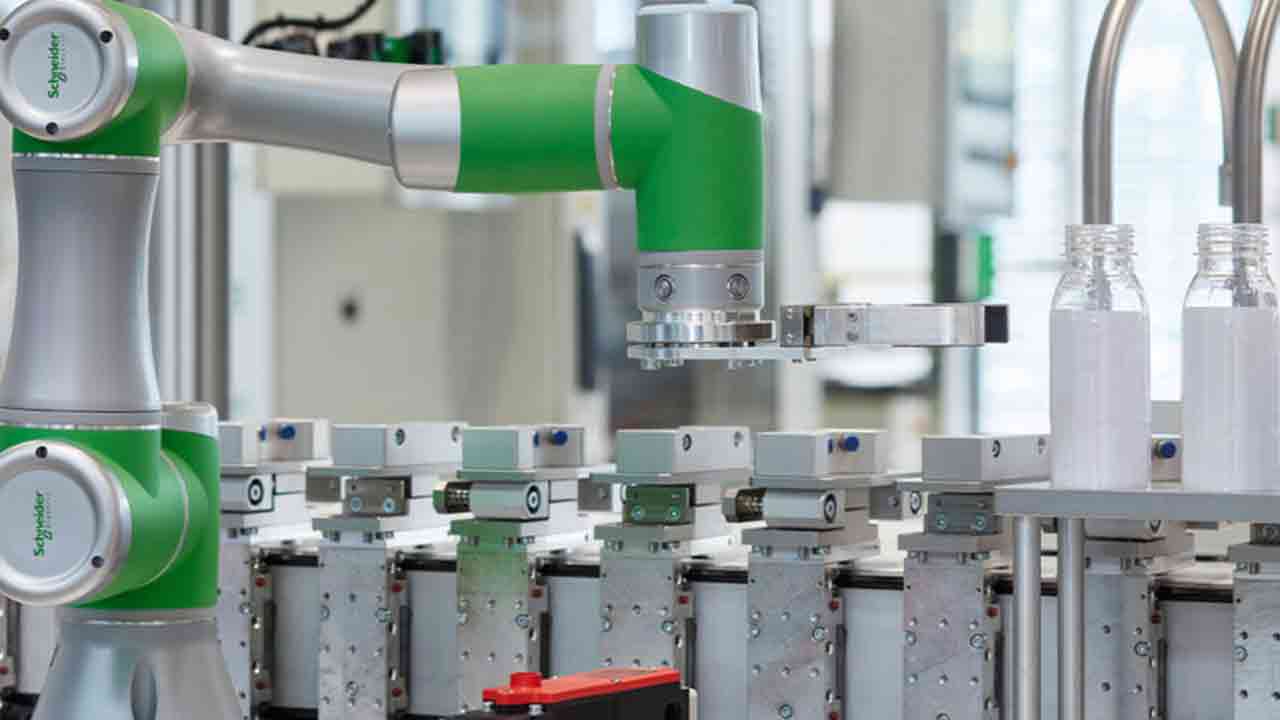

(Commonwealth)_ Schneider Electric, a global frontrunner in energy management and automation’s digital transformation, has unveiled two new collaborative robots (cobots) at MODEX 2024: the Lexium RL 3 and RL 12, with the Lexium RL 18 model set for release later this year. These cutting-edge innovations in robotics and motion control will be showcased at booth #B7232, demonstrating Schneider Electric’s commitment to addressing manufacturing challenges with precision and sustainability. The Lexium line encompasses a range of single-axis to high-performance multi-axis machines, facilitating high-speed motion and control of up to 130 axes from a single processor. This comprehensive suite aims to tackle manufacturer production, flexibility, and sustainability challenges head-on.

Schneider Electric’s approach extends beyond robotics, offering fully integrated automation systems designed digitally from inception to operation and maintenance. By integrating robots into the machine control solution through the EcoStruxure architecture, the company ensures collaborative data flow from the shop floor to the top floor. This interconnected system links smart products, robots, controls, software, and services, facilitated by Modicon motion controllers. These controllers unify PLC, motion, and robotics control functionalities on a single hardware platform, seamlessly integrated into EcoStruxure Machine Expert software, offering a holistic robotic solution.

Christine Bush, Schneider Electric’s Robotics Center of Excellence Leader, emphasizes the growing demand for smart machines in the US manufacturing sector. Customers seek robots with digital twin capabilities to validate machine performance swiftly, enabling consistent, efficient, and sustainable production ramp-ups. Schneider Electric collaborates closely with its customers, understanding their challenges and responding with tailor-made automation solutions, simplifying processes and meeting evolving needs effectively.

The compatibility of Schneider Electric’s solutions with EcoStruxure Machine Expert Twin, a digital twin software suite, enables virtual test strategies, commissioning, and shortened factory acceptance testing (FAT). Digitizing these processes can significantly reduce time-to-market by up to 50% and commissioning time by up to 60%, resulting in a substantial 20-40% reduction in investment costs.

The Lexium cobots, comprising a versatile range of robotics and automation solutions, are designed to meet the diverse needs of various industries, ranging from warehouse/logistics to life sciences and consumer packaged goods. These cobots offer a myriad of advantages that cater to the demands of modern manufacturing environments. One of the primary benefits of Lexium cobots is their capability for rapid deployment. With streamlined setup processes and intuitive interfaces, these cobots can be swiftly integrated into existing workflows, minimizing downtime and maximizing operational efficiency.

The seamless integration of Lexium cobots into diverse industrial settings is facilitated by their compatibility with open automation standards and protocols. This ensures flexibility, allowing for easy adaptation to evolving production requirements, as well as scalability to accommodate future expansion needs. Lexium cobots offer a comprehensive solution for modern manufacturing challenges. Their fast deployment, streamlined integration, consistent output, and focus on workplace health and safety make them indispensable assets across a wide range of industries, empowering businesses to optimize their operations and achieve greater efficiency and productivity.

Lexium cobots boast enhanced computing power, open software, and networking technologies, facilitating quicker assembly, installation, and maintenance. A centralized architecture with a unified programming platform promotes seamless interoperability among automation systems, machines, and robots. In terms of output consistency, Lexium cobots excel at handling repetitive tasks error-free, ensuring high-quality goods production over shorter periods, even operating 24/7 without fatigue. Additionally, they enhance workplace safety by handling risky operator tasks involving heavy weights, thereby reducing accidents and injuries.

With the rapid expansion of US manufacturing, companies are increasingly turning to digital, efficient, and sustainable solutions to meet escalating output demands. Embracing Industry 4.0’s digitization, coupled with advancements in artificial intelligence, machine learning, IoT, and digital twins, has become imperative for driving operational excellence. Schneider Electric’s Lexium motion and robotics solutions are poised to redefine efficiency and enable personalized autonomous manufacturing as the industry transitions to Industry 5.0.