(Commonwealth) _ Munich-based automaker BMW and California-based technology company NVIDIA are joining forces to develop a virtual factory that will allow for the efficient manufacturing of the all-electric Neue Klasse. This groundbreaking partnership is expected to streamline the design and production process for the highly anticipated vehicle, which is set to debut in 2025.

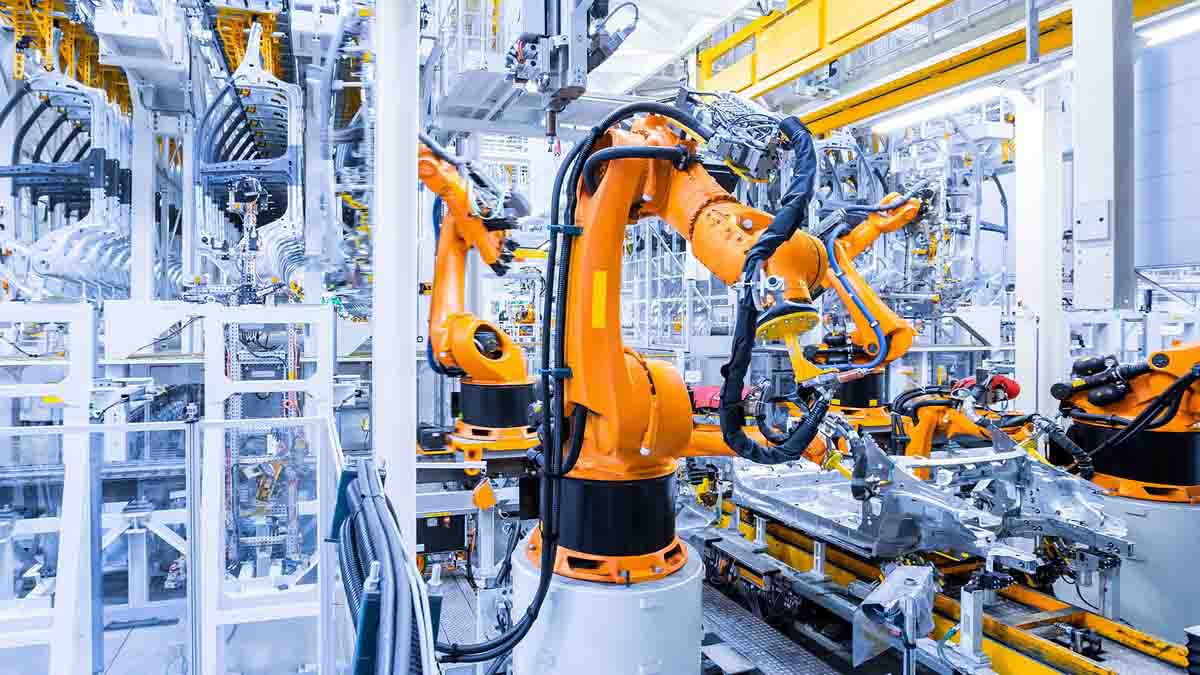

The collaboration will leverage NVIDIA’s Omniverse, a powerful simulation and collaboration platform that enables the real-time, photorealistic rendering of digital environments. With Omniverse, BMW engineers will be able to create a virtual factory that mirrors the physical production line, allowing for virtual testing and optimization of manufacturing processes before they are implemented in the real world. This will not only speed up the production process but also allow for more efficient use of resources, ultimately resulting in cost savings for the company.

BMW and NVIDIA first announced their partnership in 2019, with the goal of using advanced AI and simulation technologies to accelerate the development of new vehicles. The companies have been working closely together ever since, with BMW incorporating NVIDIA’s DRIVE platform into its vehicles for enhanced autonomous driving capabilities. The virtual factory for the Neue Klasse represents the next step in this collaboration, as the companies seek to revolutionize the way vehicles are designed and manufactured.

The Neue Klasse is set to be BMW’s first all-electric vehicle built from the ground up and is expected to compete with other high-end electric vehicles like the Tesla Model S and the Porsche Taycan. The vehicle is expected to have a range of up to 600 kilometers (370 miles) on a single charge and will be powered by BMW’s fifth-generation eDrive technology. The eDrive system features a new electric motor, a high-voltage battery, and an intelligent power electronics system, all of which are designed to maximize efficiency and performance.

The virtual factory for the Neue Klasse will allow BMW engineers to test and optimize the production process in a virtual environment, long before the physical factory is even built. This will enable the company to identify potential issues and make necessary adjustments before the actual production line is put in place. For example, engineers can test different configurations of the assembly line, adjust the placement of machines and equipment, and simulate the movement of materials and components through the production process.

By using virtual simulation to optimize the production process, BMW expects to achieve significant cost savings and efficiency gains. The company estimates that the virtual factory will reduce the time and cost of developing new vehicles by up to 50%. This will not only allow BMW to bring the Neue Klasse to market more quickly but will also enable the company to produce vehicles more efficiently in the future.

In addition to the cost savings and efficiency gains, the virtual factory for the Neue Klasse will also enable BMW to create a more sustainable production process. By optimizing the production process in a virtual environment, the company can identify and eliminate waste and inefficiencies before they occur in the physical factory. This will reduce the environmental impact of the manufacturing process and support BMW’s commitment to sustainability.

The partnership between BMW and NVIDIA represents a major step forward in the development of advanced automotive technologies. By leveraging the power of AI and virtual simulation, the companies are transforming the way vehicles are designed and manufactured, and paving the way for a more sustainable, efficient, and innovative automotive industry.

As the automotive industry continues to evolve and embrace new technologies, partnerships like the one between BMW and NVIDIA will become increasingly important. By working together, companies can leverage each other’s strengths and expertise to develop more advanced and innovative products, and ultimately deliver greater value to customers. The virtual factory for the Neue Klasse is just the beginning of what promises to be a long and fruitful partnership between these two industry leaders.